Projects

Capstone Project — Global Formula Racing

Tendon Coupler

Tractor Engine Rebuild

ENGR248 - Bike Project

Buoyancy Compensator

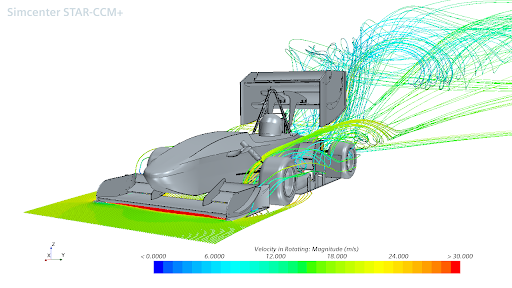

GFR Aerodynamic Development/Testing

-

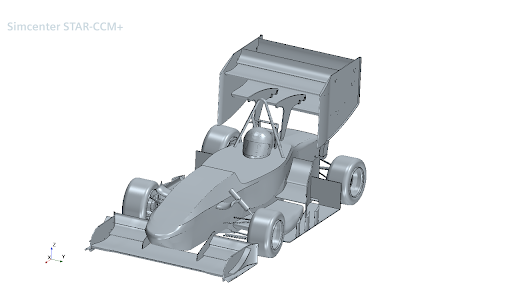

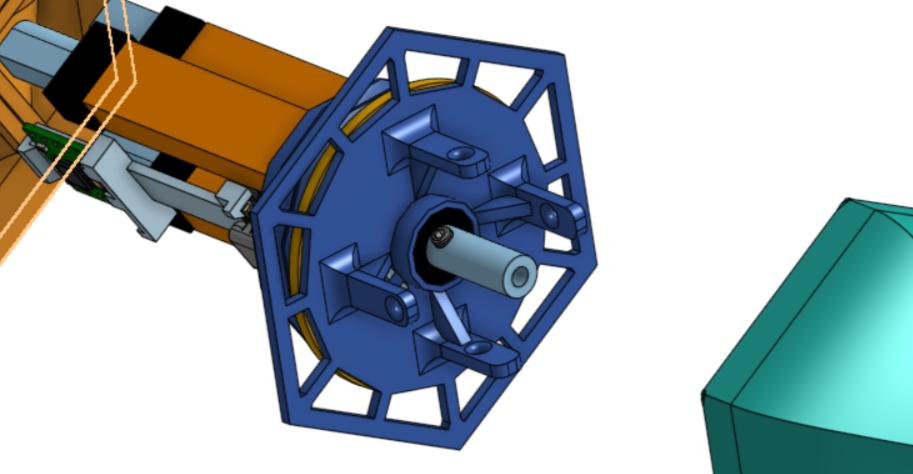

I led the front wing development for a FSAE car.

Following an iterative formula: CAD → CFD → Analysis and using Siemens NX I configured the front wing assembly (mainplane, flaps, endplates, mounts) that respected proper dimensioning, safety, and ride height constraints per FSAE rulebook.

Design iteration focused on increasing downforce, vortex generation and ground effect production while decreasing drag ratio and maintaining a aero balance for the full rake/steer envelope.

-

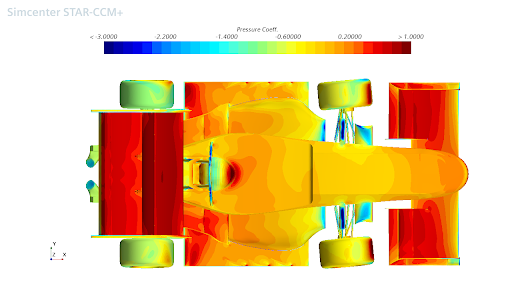

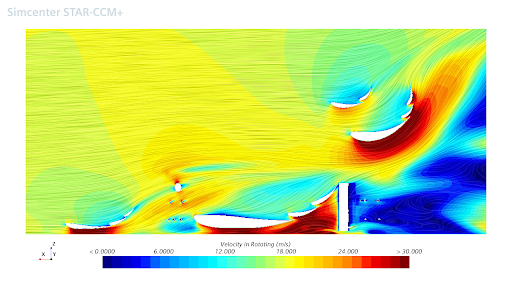

Aerodynamic analysis was driven through Simcenter STAR-CCM+ (v19) simulations. From the solver’s slideshow frames, I extracted and analyzed velocity gradients, pressure coefficients (Cp), and streamlines to explain flow features (leading-edge acceleration, endplate tip vortices, tire-wake interaction).

Output was compiled into sheets for component level and vehicle level metrics. Drag force, downforce, side force, and lift to drag (CD, CL, CS, L/D) for each vehicle component — front wing, mid body, and rear wing — as well as full car. Attitudes were weighted into an output score for overall performance.

-

This was a coordinated system design: teammates owned the mid-body and rear wing while I managed front-wing upstream flow quality. We shared simulation post-processing, and ran cross-checks to ensure front-wing wake improved under-floor and rear-wing performance.

Weekly design reviews aligned targets (downforce split, lift to drag, weighted attitudes) and gated geometry releases so the full car converged, not just individual parts.

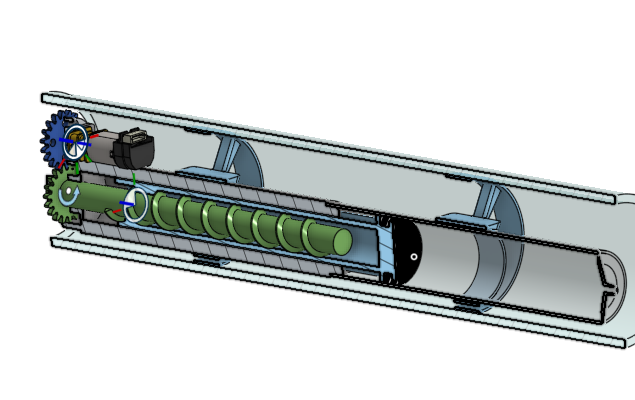

Buoyancy Compensator System – CAD Design & Prototype Development

This project presents the design and prototyping of a motor driven buoyancy compensator intended for integration into modular aquatic robotic systems. An initial proof of concept developed in OnShape, focusing on compact mechanical actuation, controllable ballast intake, and manufacturability.

The system is actuated by a 6 V geared DC motor coupled to a gear train, which drives a central shaft responsible for regulating water intake into the ballast chamber. Controlling ballast volume, the mechanism enables precise buoyancy adjustment and vertical positioning in an aquatic environment.

A first-generation functional prototype is currently being printed and manufactured to validate mechanical performance, sealing concepts, and reliability. Future development will focus on creating a more compact design with improved sealing and modular integration. The end goal of the buoyancy compensator is to be deployed alongside other subsystems within autonomous or remotely operated underwater swimmers.

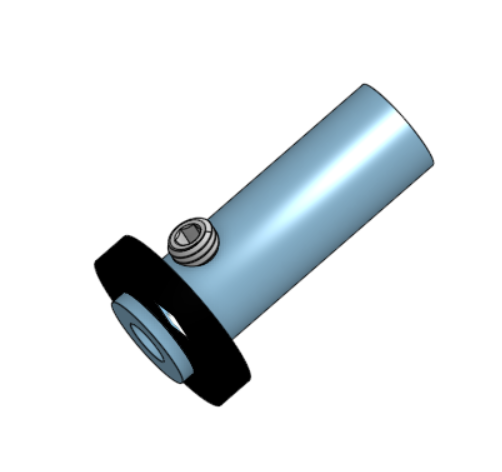

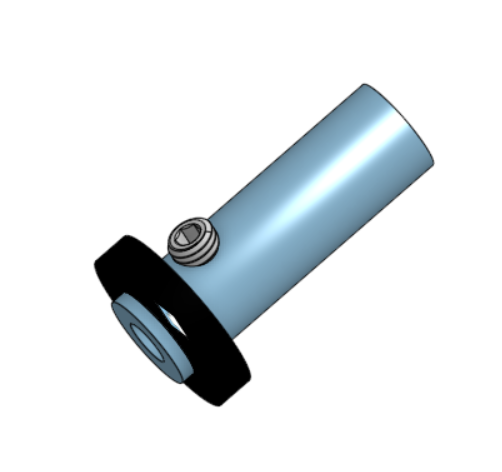

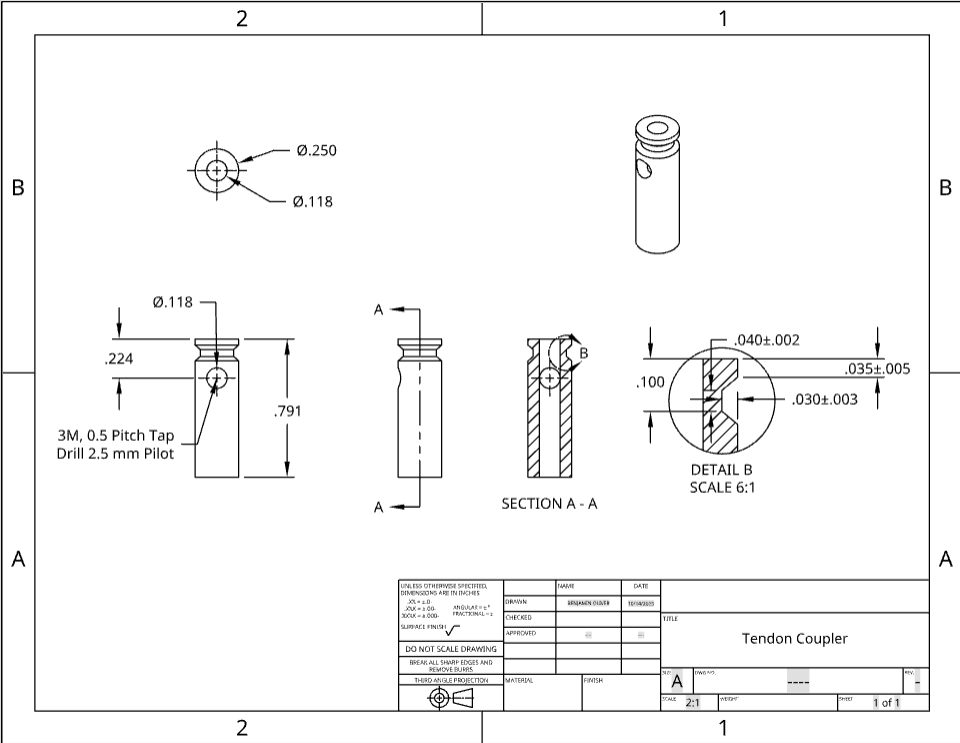

Tendon Coupler

-

Designed a compact DC motor coupling utilizing aluminum tubing and a custom 3D-printed PLA sealing washer. The design provides a watertight interface between the motor mount and electronic enclosure while maintaining precise shaft alignment. All components were fully dimensioned and toleranced per ASME Y14.5.

ENGR 248 Bike Project

-

This project was assigned to me during my sophomore year alongside three of my peers. The main outcome and goal of the project was to familiarize ourselves with Siemens NX, and deliver a concept render of a bicycle design.

-

I Worked as part of a multi-disciplinary team to design a complete bicycle prototype in Siemens NX over a 10 week period. Together as a team we coordinated component interfaces and design intent through organized team workflows, version control, and design reviews.

-

I Led the design of the bike frame, seat, and mud flap, applying GD&T principles, tolerance stack-ups, and engineering drawings as a part of the class deliverables.

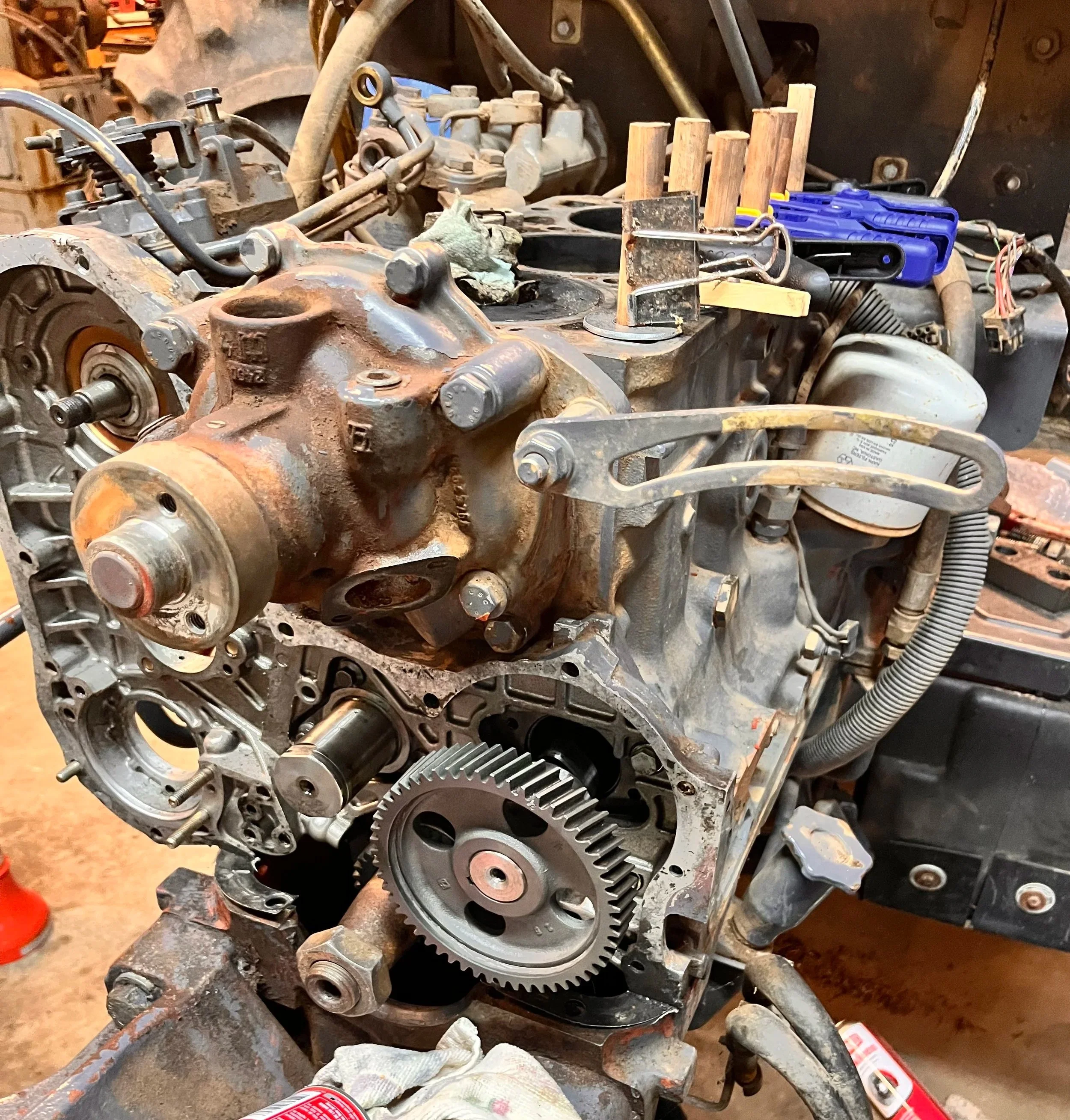

Tractor Engine Rebuild

This ongoing project involves the diagnosis and repair of a New Holland TN65 tractor engine and is being completed as time allows. The initial failure was traced to a failed bearing on the pump drive gear, which prompted removal of the front gear cover for inspection. During disassembly, a secondary failure was identified at one of the bolt holes on the rear gear cover, indicating additional structural and alignment concerns beyond the original fault.

Progress on the repair is currently constrained by the removal of the camshaft drive gear, which must be extracted to replace the rear gear cover. Conventional gear pullers have proven ineffective due to the tight interference fit between the gear and camshaft. Complete removal of the camshaft would require disassembly of the oil pump, which in turn necessitates removal of the oil sump, which happens to be a structural component of the tractor itself. This project has required my careful evaluation of disassembly sequencing, structural dependencies, and risk management to avoid unintended damage.

General Resume

This is my general resume with a broad overview of the work I have done and skills I have acquired